Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

Leaks in plumbing systems can cause costly damage and inefficiencies. How can we effectively prevent them? Pipe clamps offer a reliable solution. In this article, you'll learn how pipe clamps help maintain system integrity and prevent leaks, ensuring plumbing reliability.

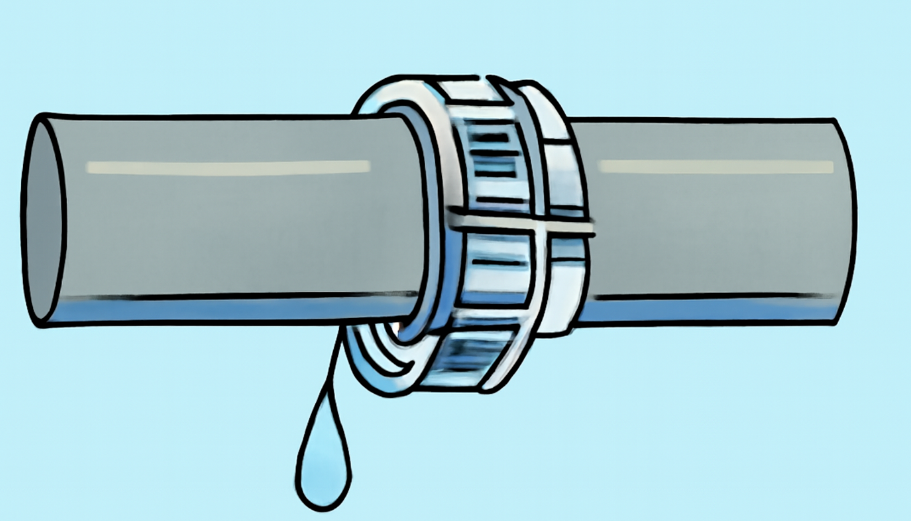

Pipe clamps work by tightly holding pipe sections together, creating a secure seal that stops water from escaping. Inside the clamp, a rubber or flexible gasket lines the inner surface, pressing firmly against the pipe when the clamp is tightened. This gasket fills any small gaps or irregularities on the pipe’s surface, blocking leaks effectively.

When you install a pipe clamp, bolts or screws draw the two halves of the clamp together. This action compresses the gasket against the pipe’s outer wall. The tighter the clamp, the stronger the seal. This tight clamping pressure is vital because even a small space can allow water to leak out, causing damage and inefficiency.

The clamp’s design also distributes pressure evenly around the pipe, preventing deformation or damage that could lead to leaks. This balance protects the pipe and maintains the integrity of the plumbing system over time.

In summary, the mechanism behind pipe clamps involves:

● A sealing gasket that conforms to the pipe surface.

● Tightening bolts that compress the gasket.

● Even pressure distribution around the pipe circumference.

Together, these features ensure water stays inside the pipes, preventing leaks and maintaining system reliability.

Note: Proper tightening of the clamp bolts is crucial; uneven or insufficient tightening can cause leaks despite using clamps.

Pipe clamps come in various materials and designs, each suited to different environments and pipe types. Understanding these options helps you choose the right clamp for your specific leak prevention needs.

Metal pipe clamps are the most common type, often made from stainless steel, galvanized steel, or other corrosion-resistant alloys. They offer:

● High Strength: Metal clamps provide robust support, ideal for industrial or high-pressure pipelines.

● Durability: Resistant to wear and corrosion, metal clamps last longer in harsh environments.

● Wide Application: Suitable for water, gas, oil, and chemical pipelines.

● Corrosion Resistance: Stainless steel clamps work well in corrosive environments, like marine or chemical plants.

These clamps consist of two semi-circular halves joined by bolts. Inside, a rubber gasket seals leaks by pressing tightly against the pipe when the clamp is tightened. Metal clamps are excellent where strength and longevity are priorities.

Plastic or composite clamps are lighter and often used in specific environments where metal clamps may not be ideal:

● Non-Corrosive: Plastic clamps resist rust and corrosion, perfect for water supply lines and drainage systems.

● Electrical Insulation: They prevent electrical conduction, useful near electrical installations.

● Lightweight: Easier to handle and install in tight spaces.

● Cost-Effective: Usually less expensive than metal clamps for low-pressure applications.

These clamps often feature a durable plastic body with a flexible gasket inside. They fit well on pipes made from PVC, CPVC, or other plastic materials. However, they are generally not suited for high-pressure or high-temperature systems.

Clamp Type | Material Examples | Best For | Advantages | Limitations |

Metal | Stainless steel, steel | Industrial, high-pressure pipes | Strong, durable, corrosion-resistant | Heavier, costlier |

Plastic/Composite | PVC, nylon composites | Low-pressure, water, drainage | Lightweight, non-corrosive, insulating | Less strength, limited temp range |

Choosing the right pipe clamp depends on the pipe material, environment, and pressure requirements. Metal clamps suit heavy-duty applications, while plastic clamps fit well in lighter, non-corrosive settings.

Proper installation plays a crucial role in ensuring pipe clamps prevent leaks effectively. Even the best pipe clamp can fail if not installed correctly. Here’s a step-by-step guide to help you prepare and install pipe clamps for maximum leak prevention.

1. Measure the Pipe and Leak Area: Determine the pipe’s outer diameter and wall thickness. Identify the exact location and size of the leak. This helps you select the right clamp size and type.

2. Clean the Pipe Surface: Remove all dirt, rust, oil, and debris around the leak area. A clean surface ensures the gasket inside the clamp seals tightly against the pipe.

3. Inspect the Pipe Condition: Check for any cracks or severe corrosion near the leak. If the pipe is too damaged, a clamp might only be a temporary fix.

4. Choose the Correct Clamp: Match the clamp size and material to the pipe and environment. For example, use stainless steel clamps for corrosive areas and plastic clamps for insulated applications.

1. Position the Clamp: Place the two halves of the clamp around the pipe so the gasket aligns exactly over the leak.

2. Insert Bolts or Screws: Push bolts through the holes on both clamp halves and hand-tighten the nuts to hold the clamp in place.

3. Tighten Evenly: Use a wrench to tighten the bolts gradually, alternating diagonally between bolts. This ensures even pressure around the pipe and gasket.

4. Check the Seal: Tighten until the leak stops, but avoid over-tightening, which can damage the pipe or gasket.

5. Final Inspection: After installation, inspect the clamp for secure fit and absence of leaks. Monitor the clamp periodically to ensure it remains tight.

● Use a torque wrench if possible to apply the recommended bolt tension.

● Avoid using clamps on pipes with irregular surfaces without smoothing or repair.

● If the pipe is hot or under high pressure, consider professional installation.

Proper installation not only prevents leaks but also extends the clamp’s lifespan and keeps your plumbing system reliable.

Always tighten pipe clamp bolts gradually and evenly in a diagonal pattern to create a uniform seal and avoid leaks.

Pipe clamps offer several benefits that make them a popular choice for preventing leaks in plumbing and piping systems. They combine cost-effectiveness, durability, and ease of installation, which helps keep plumbing systems reliable and efficient.

One major advantage of pipe clamps is their affordability. Compared to other sealing or repair methods, pipe clamps are generally low-cost but provide long-lasting results. They save money by preventing water damage that leaks can cause, reducing costly repairs and downtime.

Durability is another key benefit. Metal pipe clamps, especially those made from stainless steel or galvanized steel, resist corrosion and wear. This makes them suitable for harsh environments and high-pressure systems. Even plastic or composite clamps, though less robust, can last long in the right applications, such as low-pressure water lines.

Because pipe clamps are designed to distribute pressure evenly around the pipe, they reduce the risk of damage or deformation. This helps maintain the integrity of the pipe and the plumbing system over time, making the clamp a durable solution for leak prevention.

Pipe clamps are simple and quick to install. Their two-part design allows them to be placed around pipes without needing to disconnect or drain the system in many cases. This ease of installation saves time and labor costs during both new installations and repairs.

They are versatile, fitting different pipe sizes and materials. Whether working in residential homes, commercial buildings, or industrial plants, pipe clamps adapt well. Their installation requires basic tools like wrenches, and tightening bolts evenly creates a secure, leak-proof seal.

Additionally, pipe clamps help simplify plumbing work by holding pipes firmly in place during connections or repairs. This stability makes the entire process smoother and faster, reducing the chance of errors that could cause leaks.

● Safety: By preventing leaks, pipe clamps reduce hazards like water damage, mold growth, and slip risks.

● Compliance: Using pipe clamps helps meet plumbing safety standards and building codes.

● Flexibility: Clamps can be used on various pipe materials including metal, PVC, and composite pipes.

When installing pipe clamps, always tighten bolts evenly and gradually to ensure a secure seal and avoid damaging the pipe or gasket.

Pipe clamps are often lifesavers when a sudden leak appears in a pipe. They provide a quick and effective way to stop leaks temporarily until a permanent fix can be made. These repair clamps are designed to be easy to install on-site, even under pressure or in tight spaces.

When a pipe starts leaking unexpectedly, repair clamps can be placed directly over the leak to seal it fast. They usually consist of a metal or plastic band with a rubber gasket inside. This gasket presses tightly against the pipe, blocking the leak as soon as the clamp is tightened.

The installation is straightforward:

● Position the clamp over the leak area.

● Hand-tighten the bolts or screws to hold it in place.

● Use a wrench to gradually tighten the bolts evenly.

● Check that the leak stops and the clamp fits securely.

This quick method prevents water damage and allows time to plan a permanent repair or pipe replacement. Repair clamps are especially useful in emergencies where shutting down water supply or draining the system is not feasible immediately.

While repair clamps are helpful in emergencies, they are not a permanent solution. Over time, the gasket can wear out, or the pipe underneath may deteriorate further. Here are some key points to consider:

● Temporary Fix: Repair clamps should only be used as a stopgap measure. Schedule a full repair or replacement as soon as possible.

● Pipe Condition: If the pipe is severely corroded or cracked, the clamp might not hold well or could fail quickly.

● Pressure Limits: Clamps have pressure ratings. Using them on pipes with pressure beyond their capacity can cause leaks to reoccur.

● Material Compatibility: Ensure the clamp material suits the pipe to avoid corrosion or damage.

● Installation Quality: Improper tightening or misalignment reduces effectiveness and may worsen leaks.

In emergency repairs, pipe clamps buy valuable time but must be followed by professional evaluations and permanent fixes to ensure long-term safety and reliability.

Keeping pipe clamps in good shape is essential to ensure they keep preventing leaks effectively over time. Regular inspection and proper storage can extend their lifespan and help avoid unexpected failures.

Check pipe clamps often for any signs of damage, wear, or loosening. Here’s what to look for during inspections:

● Visual Damage: Look for cracks, dents, or corrosion on metal clamps. Plastic clamps may show signs of brittleness or cracking.

● Gasket Condition: The rubber or flexible gasket inside the clamp can degrade over time. Check for hardening, cracks, or flattening that could reduce sealing ability.

● Tightness: Bolts or screws can loosen due to vibration or temperature changes. Make sure they remain tight and evenly secured.

● Leak Signs: Any moisture or water marks around the clamp indicate a potential leak or seal failure.

If you find any worn or damaged parts, replace them promptly. Re-tighten bolts carefully, avoiding over-tightening which can damage the pipe or gasket.

How you store pipe clamps affects their durability and readiness for use:

● Dry Environment: Store clamps in a dry, well-ventilated place to prevent rust or mold growth.

● Avoid Heat and Sunlight: Excessive heat or UV exposure can degrade plastic clamps and rubber gaskets.

● Organized Storage: Keep clamps sorted by size and type. This makes it easier to find the right clamp quickly when needed.

● Clean Before Storage: Remove dirt, oil, and debris before storing clamps to prevent corrosion or gasket damage.

● Protect Metal Clamps: Applying a thin layer of anti-rust oil on metal clamps can help prevent corrosion during long-term storage.

By following these maintenance and storage practices, you ensure pipe clamps stay reliable and ready for use, reducing the chance of leaks and costly repairs.

Regularly inspect pipe clamps for gasket wear and bolt tightness, and store them in a dry, cool place to maximize leak prevention performance.

Pipe clamps effectively prevent leaks by creating secure seals with their gaskets and even pressure distribution. Choosing the right clamp material and type is crucial for optimal performance. Enjoy Tools offers high-quality pipe clamps that ensure durability and reliability in preventing leaks. Their products provide excellent value by maintaining system integrity and reducing costly repairs.

A pipe clamp is a device that holds pipe sections together, using a gasket to prevent leaks by sealing gaps on the pipe surface.

Pipe clamps prevent leaks by compressing a rubber gasket against the pipe, creating a tight seal that blocks water escape.

Metal pipe clamps are durable and corrosion-resistant, ideal for high-pressure and industrial applications.

Yes, plastic pipe clamps are generally less expensive and suitable for low-pressure applications, offering good insulation.

Ensure even tightening of bolts and proper gasket alignment to prevent leaks when installing a pipe clamp.